Vapor Compression Refrigeration Cycle

Vapor compression refrigeration systems are used for a variety of cooling refrigeration applications.

Vapor compression refrigeration cycle. Vapor compression cycle thermodynamic cycle of heat pumps. Vapour compression refrigeration or vapor compression refrigeration system vcrs in which the refrigerant undergoes phase changes is one of the many refrigeration cycles and is the most widely used method for air conditioning of buildings and automobiles. We want to design a vapor compression refrigeration cycle to absorb heat from a cool environment and reject it to a warm environment. Vapour compression refrigeration cycle is the most widely used refrigeration system in this system the working fluid is a vapor.

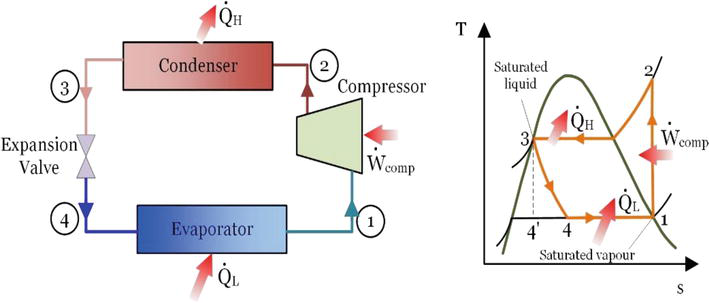

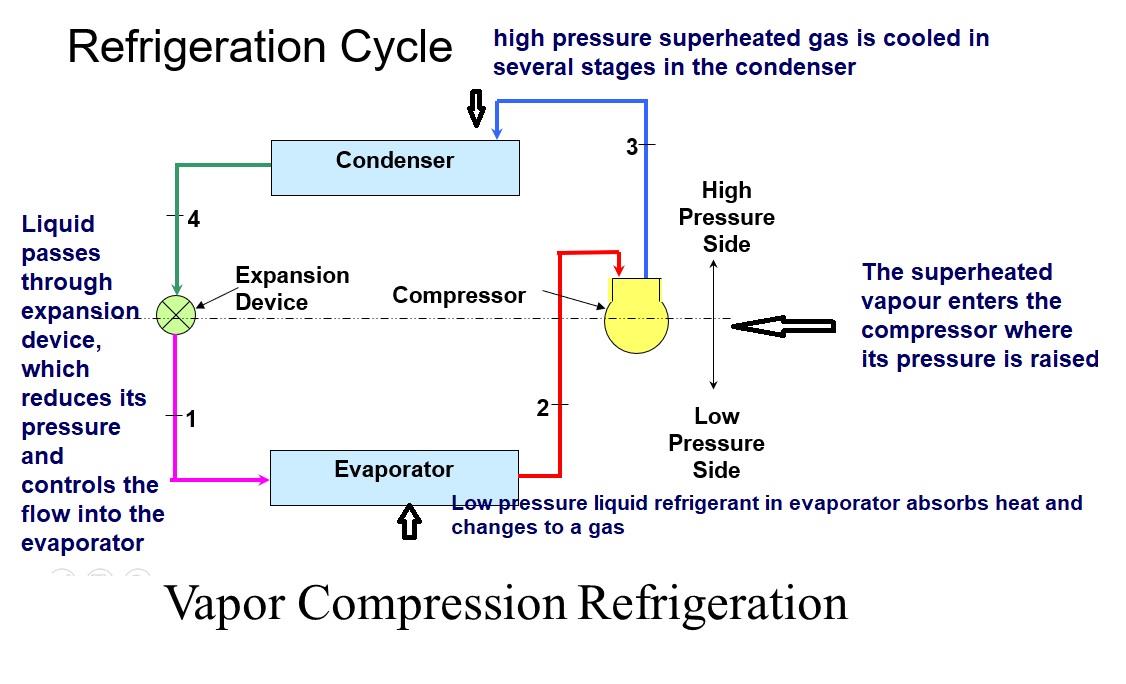

The refrigerant absorbs heat from one place and releases it to another place. Kalakul et al 2016. The vapor compression uses a circulating liquid refrigerant as the medium usually r134a which absorbs and removes heat from the space to be cooled and subsequently rejects that heat elsewhere the figure depicts a typical single stage vapor compression system the typical vapor compression system consist of four components. Vapour compression cycle generally known as vcc is a refrigeration cycle.

The coefficient of performance of the absorption refrigeration systems is very low compared to the vapor compression systems for instance the cop of the two stage lithium bromide system is about 1 1 while that of the vapor compression system used for the air conditioning applications it is about 4 to 5. Refrigeration cycles the vapor compression refrigeration cycle is a common method for transferring heat from a low temperature to a high temperature. It is a compression process whose aim is to raise the refrigerant pressure as it flows from an evaporator. The vapor compression cycle circulates a fluid through a compressor condenser expansion valve and evaporator in order to absorb heat from a refrigerated space at a low temperature and give off heat at a higher temperature to the surroundings thus keeping the refrigerated space cool.

The design problem concerns the replacement of r 134a refrigerant. A refrigerant design problem for a vapor compression refrigeration cycle was presented previously gani et al 2017. The vapor compression refrigeration cycle involves four components. It is also used in domestic and commercial refrigerators large scale warehouses for chilled or frozen storage of foods and meats.

The above figure shows the objectives of refrigerators and heat pumps. Compressor condenser expansion valve throttle valve and evaporator. In this paper the case study was extended to include an expanded search space inclusion of utility streams and practical design criteria. The purpose of a refrigerator is the removal of heat called the cooling load from a low temperature medium.

A cooler where we reject the heat a throttle a heater where we absorb the. 4 coefficient of performance cop.