Palm Oil Mill Effluent Treatment

Approximately 0 65 tonnes of raw pome is produced for every ton of fresh fruit bunches ffb processed.

Palm oil mill effluent treatment. This effluent must be treated before discharge to avoid serious environmental pollution. Palm oil mill effluent pome waste treatment plants cater all raw effluent produced. In 2003 a total of 2 106 956 tonnes of ffb were processed resulting in 1 369 521 tonnes of pome being produced. 2 1 palm oil mill effluent 10 2 2 pome generation in malaysia 14 2 3 physicochemical characteristics of pome 16 2 4 regulatory control of effluent discharge 19 2 5 pome treatment in malaysia 22 2 5 1 pretreatment of pome 22 2 5 2 primary treatment or biological pome treatment 23 2 5 3 post treatment 25.

It was estimated that a processing plant with a capacity of 10 tons fresh fruit per hour would need a water treatment plant comparable to that required by a population of half a million inhabitants brezing 1986. Palm oil mill effluent is a highly polluting material due to its high biological oxygen demand bod low ph and colloidal nature. 2 the chemical properties of pome vary widely throughout the year because of mill operations and seasonal cropping. Pome is the main cause of environmental pollution due to its high acidity high biological oxygen demand bod and chemical oxygen demand cod.

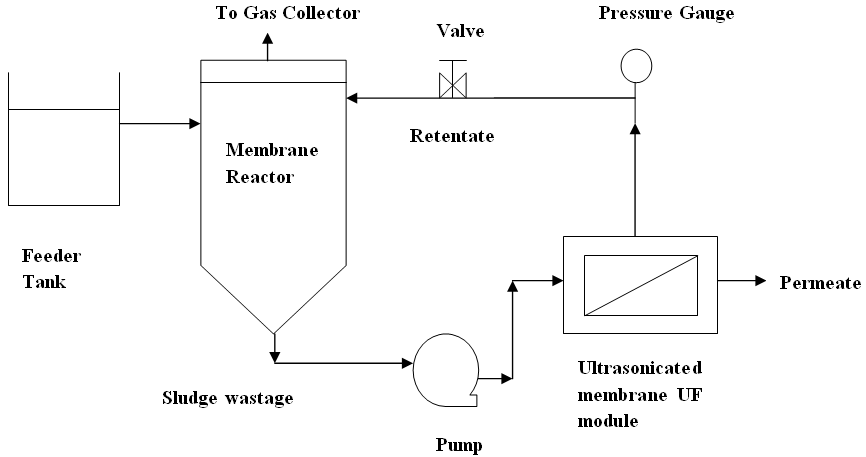

Enter mbl s efb composting system. The application of membrane separation technology coupled with adsorption treatment pre treatment can be effective means of treating palm oil mill effluent pome the pre treatment process was done by stirring the raw palm oil mill effluent pome with 0 20 g l of palm kernel shell based activated carbon pks ac in 35 94 min with stirring speed 39 82 rpm and able to reduce 71 26 of. A palm oil mill produces an average of 0 65 tons of raw palm oil mill effluent pome from every ton of ffb processed. Every year the number of palm oil mills increases rapidly thus increasing the capacity of fresh fruit bunch waste or effluent discharge.

Palm oil effluent treatment with vsep background new logic has installed a vibratory reverse osmosis system known as vsep to treat the effluent generated during the production of palm oil. Palm oil mill effluent pome is generated mainly from oil extraction washing and cleaning processes in the palm oil mill. Based on the data from the malaysian palm oil board in 2012 malaysia produced 99 85 million tons of fresh fruit bunch ffb per year. 3 atmospheric methane concentrations incredibly increased by 30 in.

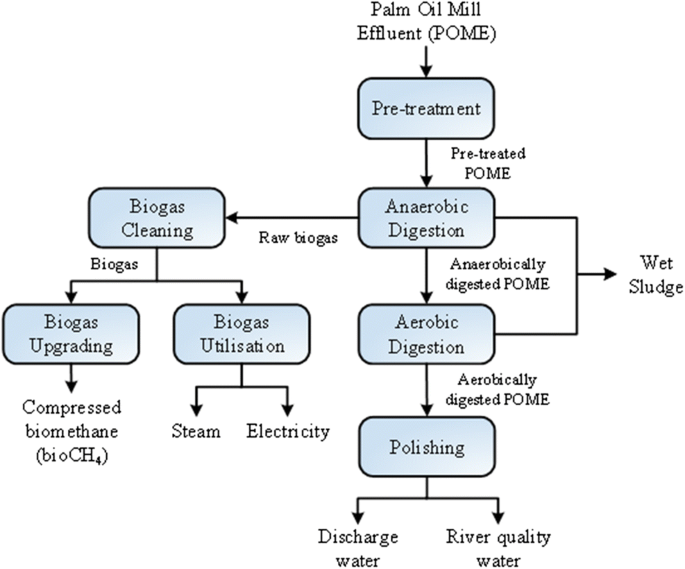

In recent decades malaysia has been known as one of the world s leading producers and exporters of palm oil products. Large and medium scale palm oil mills produce copious volumes of liquid waste from the sterilizer clarifying centrifuges and hydrocyclones. Pome cannot be discharged prior to specific treatment due to its acidic nature and very high biochemical oxygen demand bod. Liquid waste treatment involves anaerobic fermentation followed by aerobic fermentation in large ponds until the effluent quality is suitable for discharge.