Palm Oil Mill Effluent Treatment Process

Pome is the main cause of environmental pollution due to its high acidity high biological oxygen demand bod and chemical oxygen demand cod.

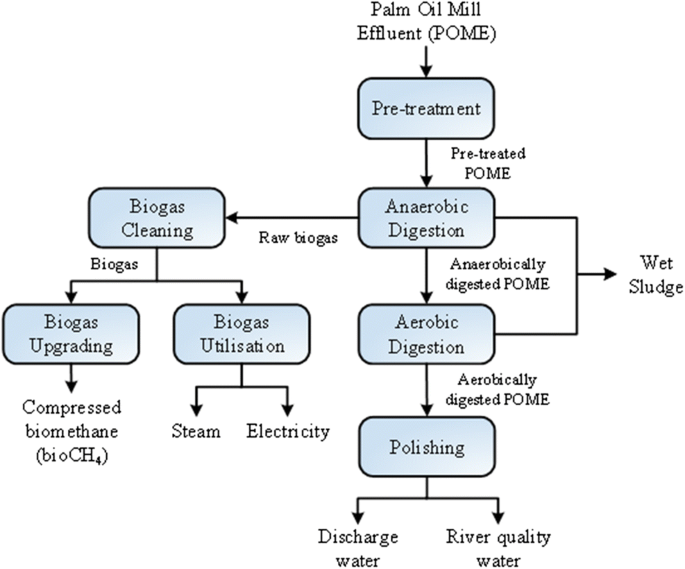

Palm oil mill effluent treatment process. Davis palm oil mill effluent. Various operating parameters such as electrolysis time inter electrode distance and initial ph were carried out to determine the efficient process condition on the removal of chemical oxygen demand cod biological oxygen demand bod and suspended solids ss. The vsep system was installed at the company s new facility in mexico near the border between mexico and guatemala. Liquid waste treatment involves anaerobic fermentation followed by aerobic fermentation in large ponds until the effluent quality is suitable for discharge.

It was estimated that a processing plant with a capacity of 10 tons fresh fruit per hour would need a water treatment plant comparable to that required by a population of half a million inhabitants brezing 1986. This effluent must be treated before discharge to avoid serious environmental pollution. According to statistical datum producing 1ton crude palm oil will generate 0 5tons water water for a 100t d palm oil mill factory it means it will produce 50tons palm oil mill effluent at least waste. Large and medium scale palm oil mills produce copious volumes of liquid waste from the sterilizer clarifying centrifuges and hydrocyclones.

Edewor a comparison of treatment methods for palm oil mill effluent pome wastes journal of chemical technology biotechnology 36. A review of methods proposed for its treatment tropical science 20 233 262 1978. Palm oil mill effluent is a highly polluting material due to its high biological oxygen demand bod low ph and colloidal nature. Electrocoagulation process using high current intensity to treat palm oil mill effluent pome was investigated in this study.

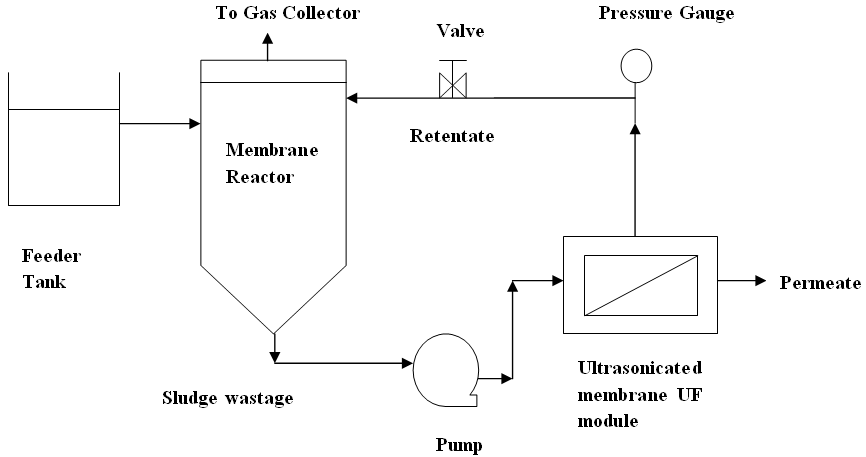

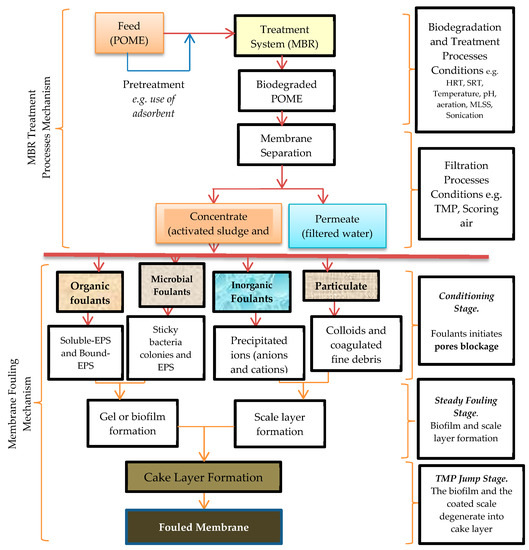

The application of membrane separation technology coupled with adsorption treatment pre treatment can be effective means of treating palm oil mill effluent pome the pre treatment process was done by stirring the raw palm oil mill effluent pome with 0 20 g l of palm kernel shell based activated carbon pks ac in 35 94 min with stirring speed 39 82 rpm and able to reduce 71 26 of. The three existing mills and the new mill can process sixty tons of oil per hour. Agamuthu palm oil mill effluent e treatment and utilization. Palm oil mill effluent pome waste treatment plants cater all raw effluent produced.

Approximately 0 65 tonnes of raw pome is produced for every ton of fresh fruit bunches ffb processed. The company using the technology operates three palm oil mills in guatemala.