Palm Oil Mill Effluent Pome Treatment System

Pool sewage treatment system is the most used and effective treatment.

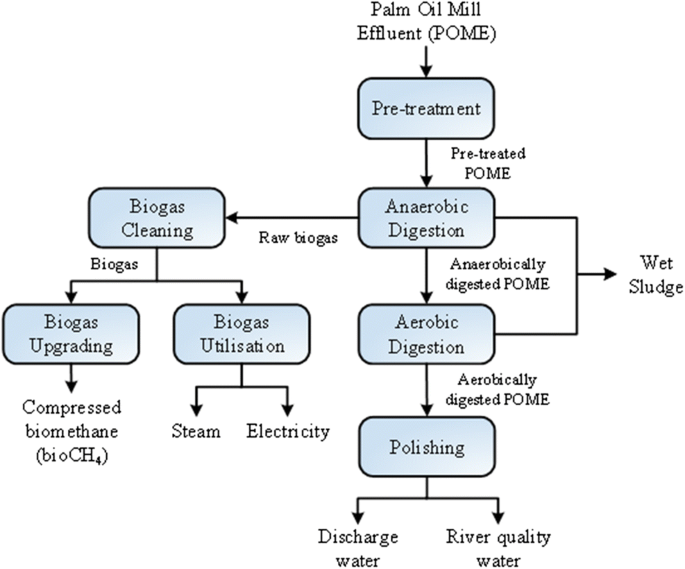

Palm oil mill effluent pome treatment system. A complete palm oil mill effluent pome treatment system using novel hybrid anaerobic aerobic bioreactor postgraduate researcher chan yi jing supervisor chong mei fong phd abstract malaysia is the world s leading producer and exporter of palm oil. 2 the chemical properties of pome vary widely throughout the year because of mill operations and seasonal cropping. It was estimated that a processing plant with a capacity of 10 tons fresh fruit per hour would need a water treatment plant comparable to that required by a population of half a million inhabitants brezing 1986. Currently some 85 of pome treat ment of more than 400 mills in the country is based on open ponding system which involves biologi.

Panied by the generation of effluent. Palm oil mill effluent is a thick brownish liquid that contains high solids oil and grease cod and bod. The waste water has high organic matter content biochemical oxygen demand bod is about 25000ppm required by qualified deal before emissions. Palm oil mill effluent pome is a viscous brown liquid with fine suspended solids at ph between 4 and 5 1 and a highly polluting wastewater that directly and indirectly contaminates the environment.

On average 1 5 m3 water is needed to pro cess 1 t of fresh fruit bunches and half of this ends up as pome. A palm oil mill produces an average of 0 65 tons of raw palm oil mill effluent pome from every ton of ffb processed. Palm oil mill effluent is a highly polluting material due to its high biological oxygen demand bod low ph and colloidal nature. Palm oil mill effluent pome is a po tential environmental pollutant.

In recent decades malaysia has been known as one of the world s leading producers and exporters of palm oil products. Pome is the main cause of environmental pollution due to its high acidity high biological oxygen demand bod and chemical oxygen demand cod. This palm oil mill effluent treatment system is cost effective only needs adequate space less investment costs. Based on the data from the malaysian palm oil board in 2012 malaysia produced 99 85 million tons of fresh fruit bunch ffb per year.

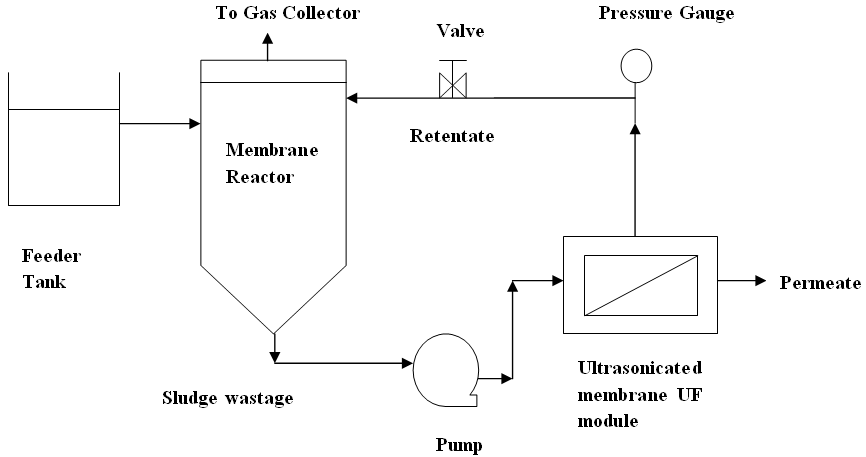

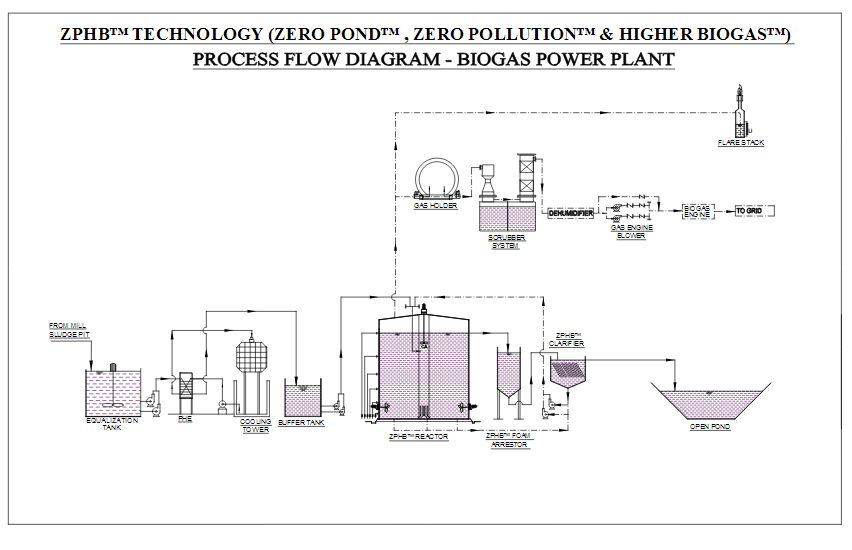

An integrated treatment system which incorporated an anaerobic aerobic wetland sequential system aawss and a convective sludge dryer csd was established to treat highly polluting palm oil mill effluent pome in a shorter retention period and with a smaller area requirement. The application of membrane separation technology coupled with adsorption treatment pre treatment can be effective means of treating palm oil mill effluent pome the pre treatment process was done by stirring the raw palm oil mill effluent pome with 0 20 g l of palm kernel shell based activated carbon pks ac in 35 94 min with stirring speed 39 82 rpm and able to reduce 71 26 of.